1. Accurate Reverse Engineering

3D scanning enables engineers to capture precise measurements of existing components, allowing for accurate reverse engineering. This is particularly useful for replicating or improving parts without original design documents.

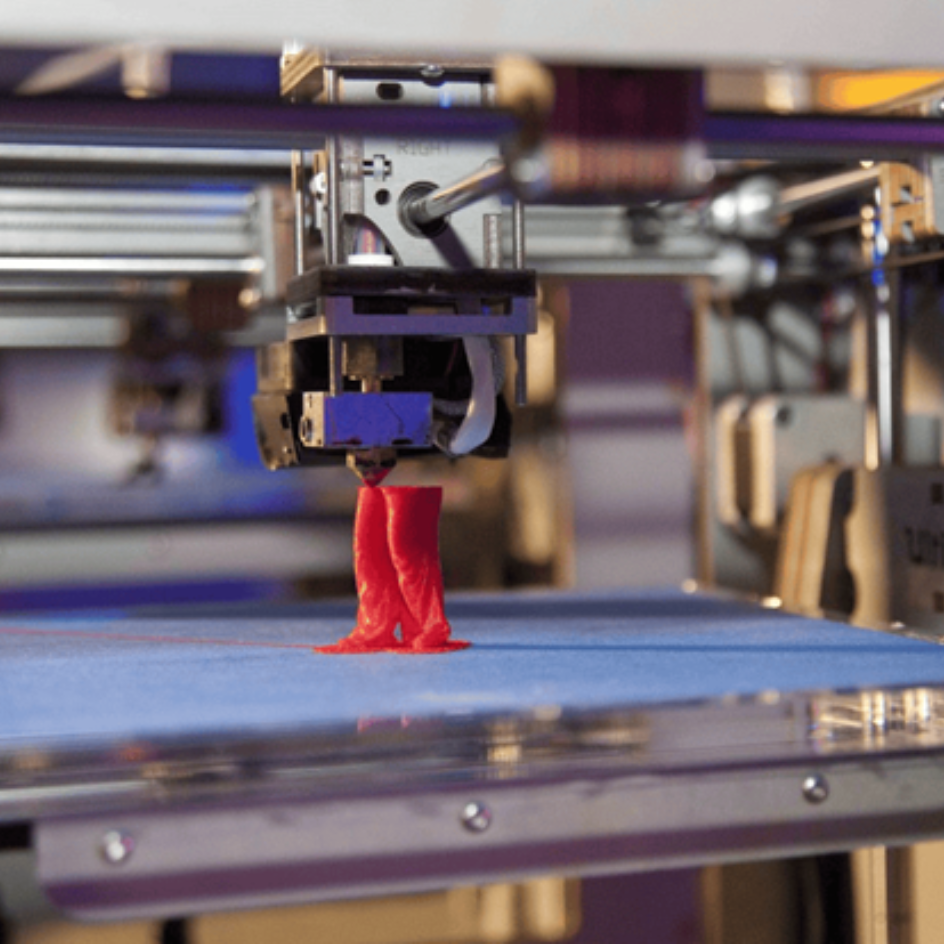

2. Rapid Prototyping and Product Development

By creating detailed digital models, 3D scanning accelerates prototyping. Engineers can quickly test and modify designs, reducing development time and bringing products to market faster.

3. Quality Control and Inspection

3D scanning provides high-resolution data for inspecting manufactured parts. Engineers can compare scanned models to original CAD files, ensuring components meet strict quality standards and specifications.

4. Complex Geometry Analysis

For intricate components with complex geometries, 3D scanning offers precise measurements that traditional tools cannot achieve. This is essential in aerospace, automotive, and custom fabrication projects.

5. Enhanced Collaboration and Digital Archiving

3D scanned data can be shared easily with teams across different locations, improving collaboration. It also allows for creating digital archives of parts and assemblies, useful for future reference and modifications.

6. Cost and Time Savings

By reducing manual measurements and errors, 3D scanning saves significant time and costs during the design, prototyping, and production stages.

Conclusion

3D scanning is reshaping Brisbane’s engineering landscape by improving accuracy, efficiency, and innovation. At DK Engineering & Machining, we harness this technology to deliver cutting-edge solutions for industries across Queensland. Whether it’s reverse engineering, prototyping, or quality control, 3D scanning ensures precision and reliability in every project.